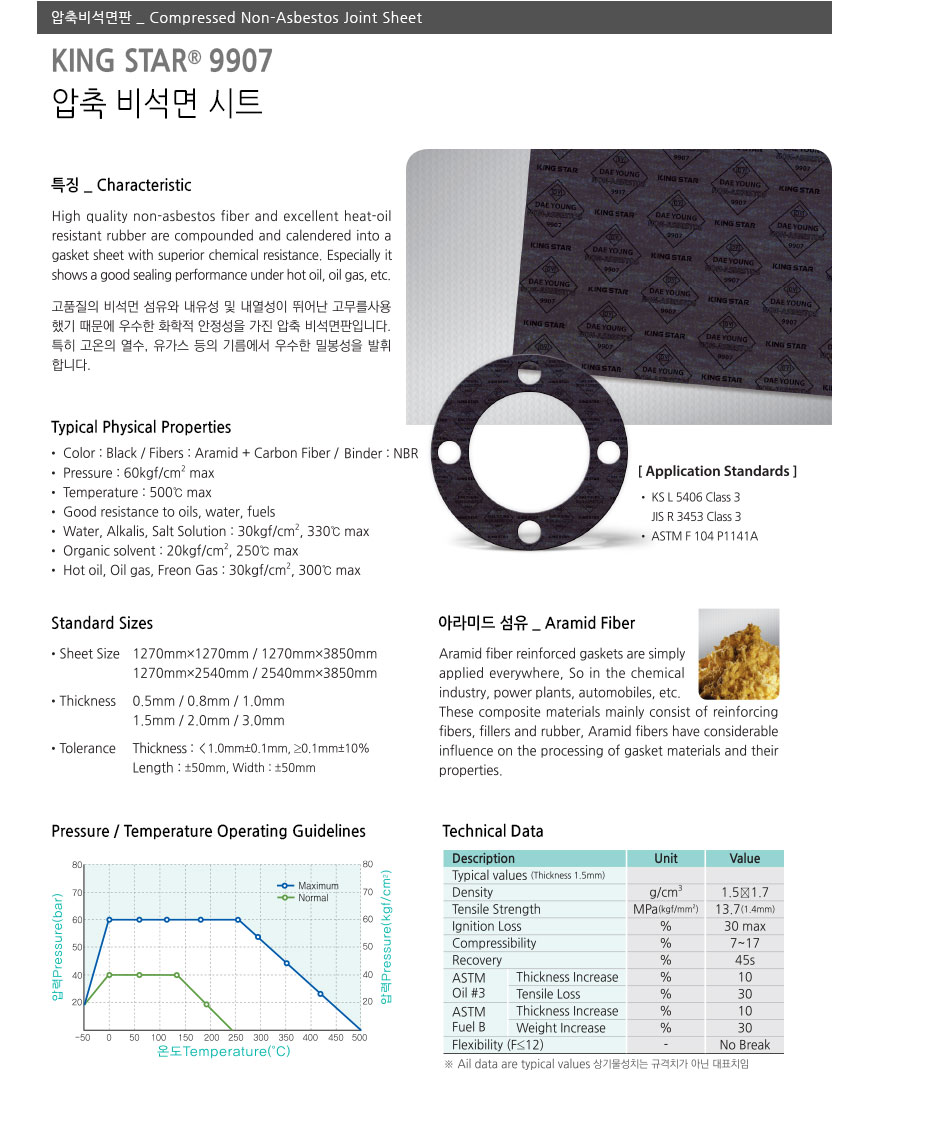

| DY #9907 | | | 압축비석면판

Compressed Non-Asbestos Joint Sheet |

| | |

|

| |

|

| |

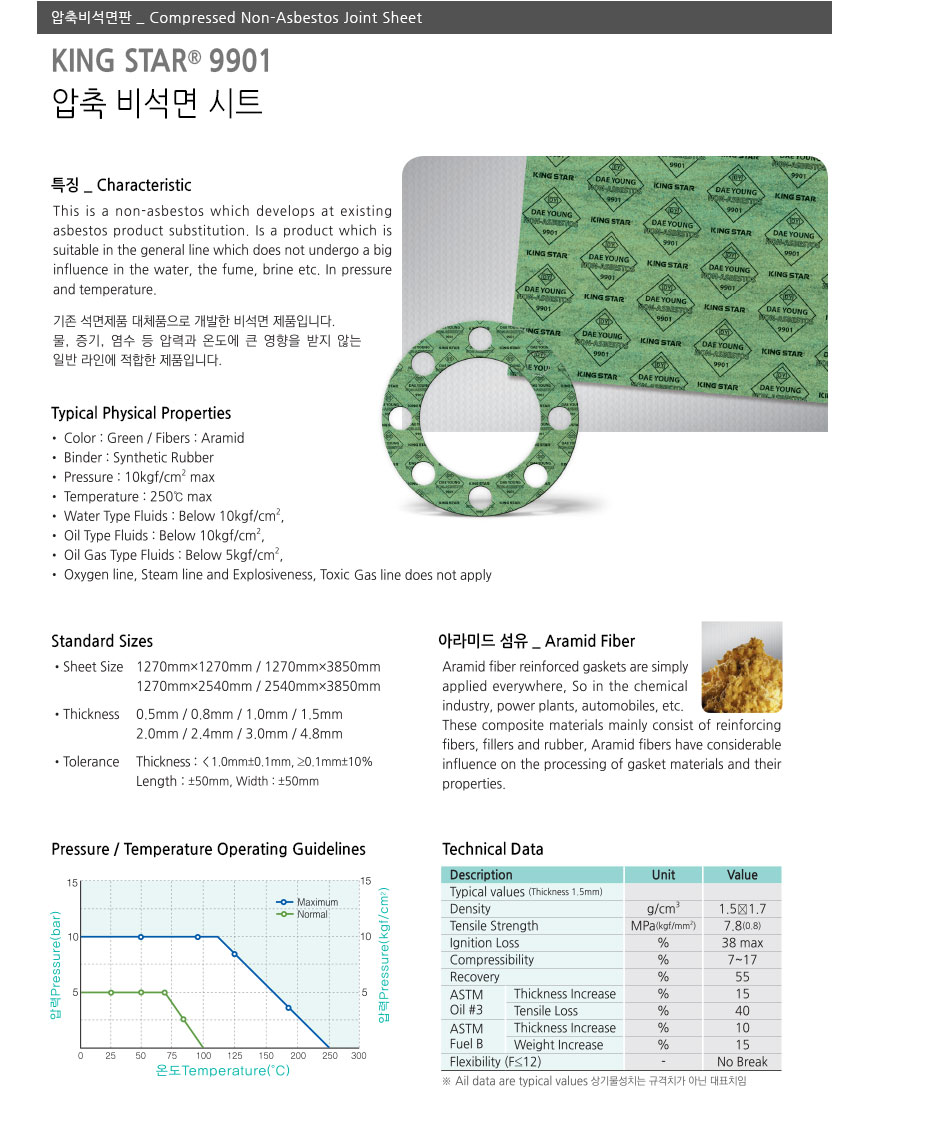

| Color : Black Fibers : Aramid Binder : NBR Pressure : 60 kgf/㎠ Temperature : 430 ℃ Max. Good resistance to Hot Oil / Fuels / Water Water, Alkalis, Salt Solution : 30 kgf/㎠, 330 ℃ Max Organic solvent : 20 , 250 Max |

| |

|

| |

고품질의 비석면 섬유와 내유성 및 내열성이 뛰어난 구무를 사용했기 때문에 우수한 화학적 안정성을 가진 압축 비석면판이다. 특히 고온의 열수, 유가스등의 기름에서 우수한 밀봉성을 발휘한다.

High quality non-asbestos fiber and excellent heat-oil resistant rubber are compounded and calendered into a gasket sheet with wuperio chemical resistance. Especially it shows a good sealing performance under hot oil, oil gas, etc. |

| |

|

| |

Sheet Size : 1270 × 1270mm / 1270 × 3850mm

Sheet Size : 1270 × 2540mm / 2540 × 3850mm Thickness : 0.5mm / 0.8mm / 1.0mm

Thickness : 1.5mm / 2.0mm / 3.0mm Tolerance : Thickness : < 1.0mm ± 0.1mm, ≥ 0.1mm ± 10%

Tolerance : Length : ± 50mm, Width : ± 50mm |

| |

|

| |

| KS L 5406 Class 3 / JIS R 3453 Class 3 ASTM F 104 P1141A |

| |

|

| |

| | Aramid fiber reinforced gaskets are simply applied everywhere, So in the chemical industry, power plants, automobiles, etc. These composite materials mainly consist of reinforcing fibers, fillers and rubber, Aramid fibers have considerable influence of the processing of gasket materials and their properties. |

|

| |

|

| |

| Description | Unit | Value | | Typical values (Thickness 1.5mm) | | | | Density | g/㎤ | 1.5 ~ 1.7 | | Tensile Strenght | kgf/㎟ | 1.4mm | | Ignition Loss | % | 38 max | | Compressibility | % | 7~17 | | Recovery | % | 45s | ASTM

Oil#3 | Thickness Increase | % | 15 | | Tensile Loss | % | 30 | ASTM

Fuel B | Thickness Increase | % | 10 | | Weight Increase | % | 30 | | Flexibility (F≤12) | - | No Break |

|

※Ail data are typical values

※ 상기물성치는 규격치가 아닌 대표치임

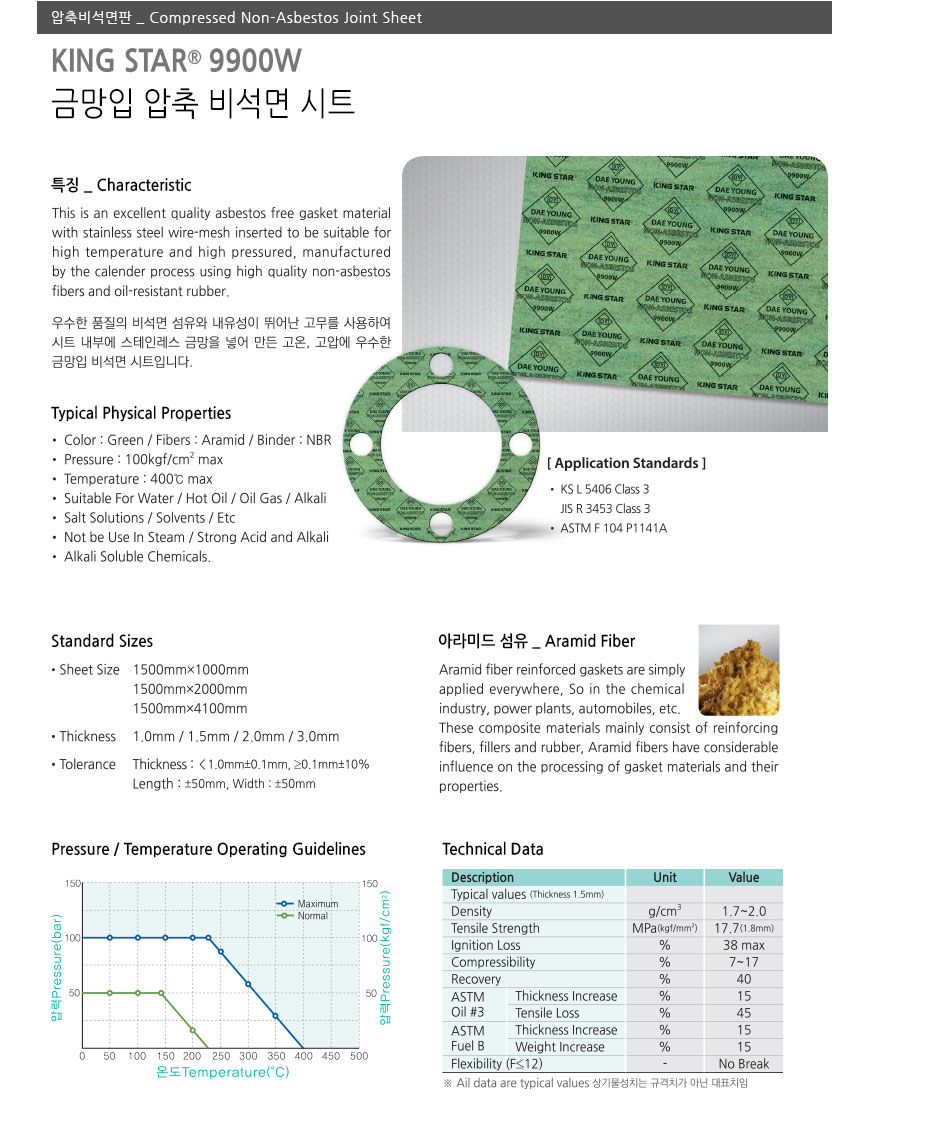

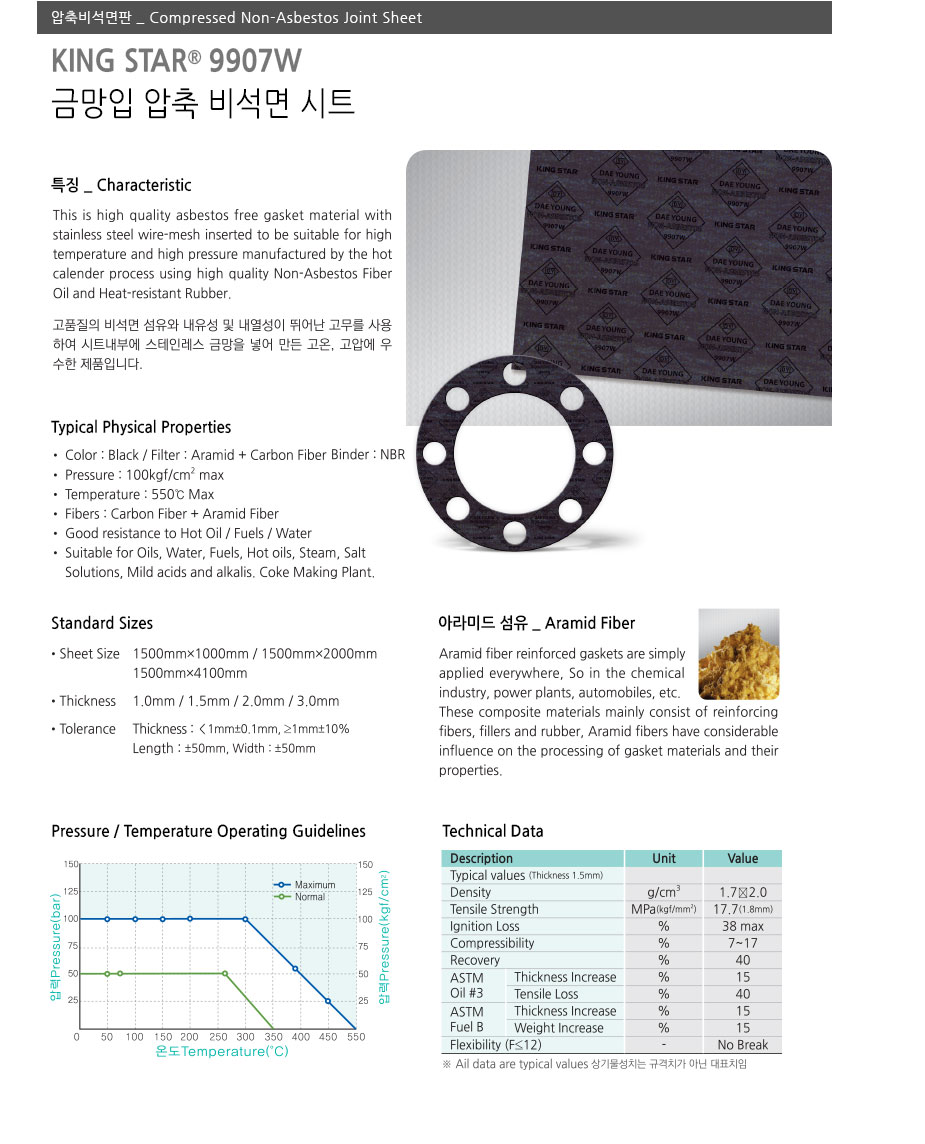

| DY #9900-W | | | 금망입 압축비석면판

Wire Reinforced Compressed Non-Asbestos Joint Sheet |

| | |

| | | | | | | Color : Green Fibers : Aramid Binder : NBR Pressure : 100 kgf/㎠ Temperature : 400 ℃ Max. Suitale For Water / Hot Oil / Oil Gas / Alkali Salt Solution / Solvents / Etc Not be Use in Steam / Strong Acid and Alkali Alkali Soluble Chermicals. | | | | | | 우수한 품질의 비석면 섬유와 내유성이 뛰어난 고무를 사용하여 시트 내부에 스테인레스 금망을 넣어 만든 고온, 고압에 우수한 금망입 비석면 시트입니다.

This is an excellent quality asbestos free gasket material with stainless steel wire-mash inserted to be suitable for high temperature and high pressured, manufactured by the calender process using high quality non-asbestos and oil-resistant rubber. | | | | | | Sheet Size : 1270 × 1270mm / 1270 × 3850mm

Sheet Size : 1270 × 2540mm / 2540 × 3850mm

Sheet Size : 1500 × 2000mm / 1500 × 4000mm Thickness : 0.5mm / 0.8mm / 1.0mm

Thickness : 1.5mm / 2.0mm / 3.0mm Tolerance : Thickness : < 1.0mm ± 0.1mm, ≥ 0.1mm ± 10%

Tolerance : Length : ± 50mm, Width : ± 50mm | | | | | | | KS L 5406 Class 3 / JIS R 3453 Class 3 ASTM F 104 P1141A | | | | | | | | Aramid fiber reinforced gaskets are simply applied everywhere, So in the chemical industry, power plants, automobiles, etc. These composite materials mainly consist of reinforcing fibers, fillers and rubber, Aramid fibers have considerable influence of the processing of gasket materials and their properties. |

| | | | | | | Description | Unit | Value | | Typical values (Thickness 1.5mm) | | | | Density | g/㎤ | 1.7 ~ 2.0 | | Tensile Strenght | kgf/㎟ | 1.4mm | | Ignition Loss | % | 38 max | | Compressibility | % | 7~17 | | Recovery | % | 40 | ASTM

Oil#3 | Thickness Increase | % | 15 | | Tensile Loss | % | 45 | ASTM

Fuel B | Thickness Increase | % | 15 | | Weight Increase | % | 15 | | Flexibility (F≤12) | - | No Break |

| ※Ail data are typical values

※ 상기물성치는 규격치가 아닌 대표치임 |

|